History

- Corporate history

- Technological history

-

1968-2000

First stageCrafting innovation from the ground up

-

2001-2020

Second stageA period of expansion

-

2021-

Third stageToward the next leap forward — Innovation begins at the edge.

1968-2000First Stage: Crafting innovation from the ground up

In 1968, Masanori Furuya founded Furuya Metal Co., Ltd., laying the foundation for a company that would later become a pioneer in industrial precious metals.

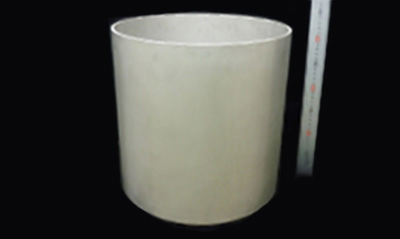

After years of perseverance through challenging times, the company achieved a breakthrough in 1981 by successfully producing Japan’s first iridium crucible.

With the establishment of the Tsukuba Plant and continued advances in processing technologies, Furuya Metal built a strong foundation as a manufacturer specializing in iridium(Ir) and ruthenium(Ru)—precious metals renowned for their difficulty to handle. The technological expertise cultivated during this period continues to define Furuya Metal today.

1968

Establishment of Furuya Metal

On August 22, 1968, Furuya Metal Co., Ltd. was founded.

The company traces its roots to Furuya Shoten, a precious metal sales business established in March 1951 by Masanori Furuya—the father of current chairman Takehito Furuya—at their home in Mitakadai, Tokyo.

At its founding, the company primarily sold precious metals for jewelry.

1975

Entry into the industrial precious metal business

Furuya Metal shifted from jewelry to industrial precious metals, marking a major turning point.

The company’s manufacturing journey began in a converted garage at the founder’s home, which became the starting point of its craftsmanship and technological development.

1977

Relocation of head office and plant to Takada

As business expanded, the head office and plant were relocated from Mitakadai to Takada, Toshima-ku, Tokyo.

The new site—formerly a warehouse—was renovated into the company’s plant.

1981

Successful production of Japan’s first iridium crucible

Furuya Metal achieved a historic milestone by manufacturing Japan’s first domestically produced iridium crucible, which until then had been available only from overseas manufacturers.

1982

Establishment of the Takada Plant

To increase production capacity, the company opened its second facility, the Takada Plant, specializing in industrial precious metals.

Employees at the time fondly referred to the site as “Takadanobaba.”

1983

Signed precious metal bullion trading contract with Mitsubishi Corporation

Began agency sales for the Precision Materials Division of Shin-Etsu Chemical Co., Ltd.

Utilizing its business experience with universities and research institutions, the company began agency sales of PBN (Pyrolytic Boron Nitride) crucibles manufactured by Shin-Etsu Chemical Co., Ltd.

1989

Joint development of a continuous temperature measurement thermocouple for molten pig iron and steel with Nippon Steel Corporation and Asahi Glass Co., Ltd.

Furuya Metal jointly developed a continuous temperature measurement thermocouple with Nippon Steel Corporation (now Nippon Steel & Sumitomo Metal Corporation) and Asahi Glass Co., Ltd. (now AGC Inc.) to measure the temperature inside blast furnaces in real time during the steelmaking process.

Conventional thermometers could not withstand the extremely high temperatures inside the furnace, making continuous measurement impossible.

The newly developed thermocouple enabled continuous and accurate real-time monitoring of furnace temperatures.

1990

Establishment of the Tsukuba Plant and consolidation of the head office and Takada plants

The head office and Takada plants were consolidated into the newly established Tsukuba Plant in Shimodate City, Ibaraki Prefecture (now Chikusei City).

This marked the end of the “Takadanobaba era” and the beginning of a new chapter in large-scale manufacturing.

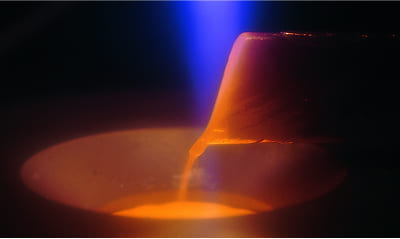

Development of plasma melting technology

Working with an equipment manufacturer, Furuya Metal developed a plasma melting furnace that eliminated the need for ceramic crucibles—achieving significantly higher purity in the melting process.

1991

Joint Development of High-Temperature Sensors with the National Aerospace Laboratory of Japan

With support from the Science and Technology Agency, Furuya Metal and the National Aerospace Laboratory of Japan (now part of JAXA) jointly developed iridium-alloy high-temperature sensors capable of measuring gas temperatures around 1,900 °C.

1993

Direct Procurement of Precious Metal Bullion

Furuya Metal began direct procurement of precious metal bullion from Western Platinum Limited in South Africa, ensuring a stable and reliable supply of raw materials.

1995

Development of a Nitric Acid–Free Platinum Refining System

Furuya Metal developed an innovative refining process that eliminated the use of aqua regia, reducing environmental impact and improving efficiency.

This expertise later contributed to breakthroughs in the refining of iridium and ruthenium.

1997

Development of the Iridium Direct Dissolution System

To address soaring demand for iridium compounds, Furuya Metal invented a completely new dissolution technology that dramatically improved refining speed and efficiency.

Automated in-house equipment further expanded capacity, giving the company an iridium refining capability comparable to major mining firms.

1998

Establishment of the Tsukuba Research and Development Center

Within the Tsukuba Plant, Furuya Metal established an R&D Center dedicated to advancing thin-film technologies.

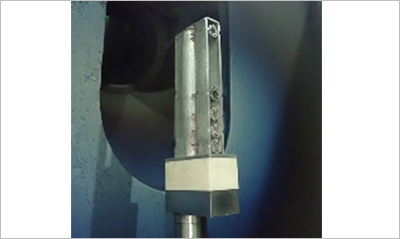

Development of Wafer Thermocouples

Furuya Metal developed wafer thermocouples for precise temperature measurement in semiconductor manufacturing, enabling accurate verification of internal equipment temperatures.

1999

Development of APC material

Furuya Metal developed APC, a silver alloy composed of silver (Ag), palladium (Pd), and copper (Cu), which offers outstanding corrosion resistance.

Optical discs—originally CD-Rs—had used gold as the reflective layer material, but APC was adopted as a cost-effective alternative with superior corrosion resistance.

The material continues to be used today in Blu-ray Discs.

2000

ISO 9001 certification acquired at the Tsukuba Plant

To reinforce quality management across all product categories, Furuya Metal obtained ISO 9001 certification, the international standard for quality assurance.

Completion of the PGM removal system

Furuya Metal completed the development of a PGM removal system, enabling the recovery and refining of high-purity iridium from used iridium crucibles.

2001-2020Second stage: A period of growth and global expansion

As business expanded, Furuya Metal entered a new stage of technological innovation and global outreach. The company established the Tsuchiura and Chitose Plants to focus on research and development of high-performance products, further enhancing its production and R&D capabilities.

Following its listing on the JASDAQ market, Furuya Metal accelerated global business development with the vision of becoming the world’s No. 1 company in iridium and ruthenium.

Through the creation of products that achieved leading global market shares, Furuya Metal was selected as a Global Niche Top Company by Japan’s Ministry of Economy, Trade and Industry in both 2014 and 2020—a testament to its continued technological excellence and international competitiveness.

2001

Development of FPO alloy

Furuya Metal developed FPO, a platinum alloy strengthened by oxide dispersion, using proprietary technology.

This innovation became one of the company’s core products, serving as a critical material for platinum equipment used in the production of functional glass.

2002

Development and introduction of the ruthenium direct dissolution system

Furuya Metal created an innovative recycling technology that allows for the efficient and high-purity recovery of ruthenium—a metal traditionally difficult to dissolve and recycle.

The simplified process significantly improved both yield and sustainability, contributing to the company’s resource-circulation efforts.

Establishment of the Research and Development Department

To drive technological progress across a wide range of disciplines—including materials, sensors, thin-film materials, chemical compounds, refining, and recycling—Furuya Metal established a dedicated Research and Development Department comprising three divisions: Materials, Thin Film, and Chemical.

While each division specializes in distinct technologies, close collaboration and active knowledge sharing among them have led to new research initiatives and solutions to complex technical challenges.

2003

Construction of Building B at the Tsukuba Plant

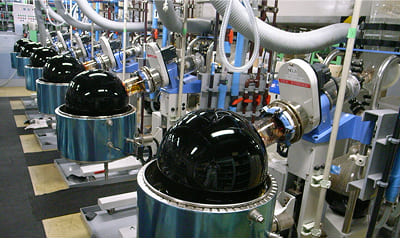

Furuya Metal completed Building B within the Tsukuba Plant premises, expanding its production capacity with new facilities dedicated to manufacturing ruthenium sputtering targets used in hard disk drives (HDDs).

2004

Full-scale launch of ruthenium refining

Furuya Metal began full-scale ruthenium refining at the Tsukuba Plant with the production of ruthenium compounds used as oxidation catalysts in the petrochemical industry.

Initially, a prefabricated hut was constructed and equipped with distillation apparatus to enable small-batch refining and process development. Through this setup, the company refined its techniques and successfully established the core technologies for ruthenium refining.

These technologies later formed the foundation for a large-scale refining line with an annual capacity of 10 tons, completed in Building C of the Tsukuba Plant the following year.

2005

Construction of Building C at the Tsukuba Plant

To meet rapidly increasing demand for ruthenium refining, Furuya Metal expanded Building C at the Tsukuba Plant—where PGM recovery, recycling, and compound development had already been underway.

Obtained certification from the London Platinum and Palladium Market (LPPM)

Furuya Metal successfully passed the rigorous technical examination conducted by the London Platinum and Palladium Market (LPPM)—the international accreditation body that sets global standards for platinum and palladium refining.

As a result, the company was officially registered as an approved melter and assayer (Good Delivery refiner).

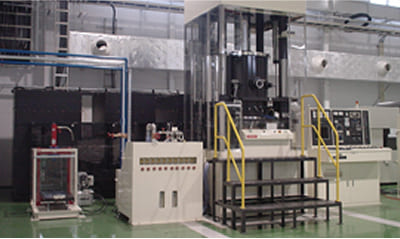

Introduction of the first SPS unit

Furuya Metal introduced its first SPS (Spark Plasma Sintering) unit—a cutting-edge technology that enables the rapid densification of powder samples through high-speed heating.

This installation at the Tsukuba Plant marked an important step in enhancing the company’s materials processing capabilities and advancing its research into next-generation functional materials.

Ruthenium targets adopted for mass production in hard disk drives

Ruthenium targets developed by Furuya Metal were adopted for mass production in hard disk drives (HDDs) utilizing the perpendicular magnetic recording method—a breakthrough that enabled compact, lightweight devices with significantly larger storage capacities.

2006

Acquisition of ISO 14001 certification at the Tsukuba Plant

As Furuya Metal expanded into the chemical business and began handling a broader range of chemical materials, the company obtained ISO 14001 certification, the international standard for environmental management systems.

This certification strengthened its initiatives to manage and reduce environmental risks.

Listed on the JASDAQ Securities Exchange

On September 27, 2006, Furuya Metal became the first industrial precious metal manufacturer to be listed on the JASDAQ Securities Exchange.

At this time, the corporate slogan “The world’s No.1 in iridium and ruthenium” was introduced.

Development of NEW-APC

Furuya Metal developed NEW-APC, an enhanced version of its original silver alloy APC, first introduced in 1999.

While maintaining the excellent corrosion resistance of the original material, NEW-APC offers significantly improved heat resistance and higher reflectivity.

This advanced alloy is primarily used in display applications, including LCDs and OLEDs.

2007

Construction of Building D at the Tsukuba Plant

To expand production capacity for temperature sensors (thermocouples) used in semiconductor manufacturing equipment, Furuya Metal constructed Building D within the Tsukuba Plant premises.

The new facility also laid the groundwork for the future expansion of target production.

Establishment of the Tsuchiura Plant and expansion of precious metal refining lines

To strengthen ruthenium refining capacity, Furuya Metal established the Tsuchiura Plant, equipping it with newly built facilities and expanded precious metal recovery and refining lines.

With the launch of this new plant, the company’s ruthenium refining capacity increased to approximately 15–20 tons per year—about double the previous level.

Opening of the Kyushu Branch Office

2008

Development of GS-FPO alloy

Furuya Metal developed GS-FPO—short for Grain Stabilized Furuya Platinum alloys with Oxide particles—an improved version of FPO, which was originally created in 2001.

This proprietary, high-performance platinum alloy maintains elongated crystal grains even at temperatures as high as 1,500 °C, significantly extending the service life of platinum equipment used in glass melting processes.

2009

Acquisition of ISO 14001 certification at the Tsuchiura Plant

To ensure thorough environmental and quality management for products manufactured at the Tsuchiura Plant, Furuya Metal obtained ISO 14001 certification, following the precedent set by the Tsukuba Plant. Registration and accreditation as a JCSS calibration organization.

Furuya Metal was registered as a JCSS calibration organization and accredited as an international MRA-compliant JCSS business operator for the calibration of R-type thermocouples, in accordance with Japan’s Measurement Act and ISO/IEC 17025 standards.

This accreditation enables the company to provide internationally recognized calibration services that meet the highest standards of accuracy and reliability.

2010

Establishment of the Chitose Plant

Furuya Metal established the Chitose Plant to begin in-house production of quartz protection tubes used for temperature sensors (thermocouples) in semiconductor manufacturing equipment.

For years, customers had requested that Furuya Metal produce these tubes internally. The new facility made this possible, enhancing the company’s ability to deliver fully integrated, high-quality sensor products that meet diverse customer needs.

2011

Capital and Business Alliance with Tanaka Kikinzoku Kogyo K.K.

Furuya Metal entered into a capital and business alliance with Tanaka Kikinzoku Kogyo K.K., Japan’s largest precious metal manufacturer. The partnership aimed to ensure a stable supply of iridium bullion and to promote mutual collaboration across related business fields.

Establishment of FURUYA METAL KOREA Co., Ltd.

Furuya Metal established FURUYA METAL KOREA Co., Ltd. in Seoul, South Korea — its first wholly owned overseas subsidiary — to engage in the sales of industrial precious metal products.

This move strengthened the company’s sales network and customer support in the rapidly expanding Korean semiconductor and smartphone industries.

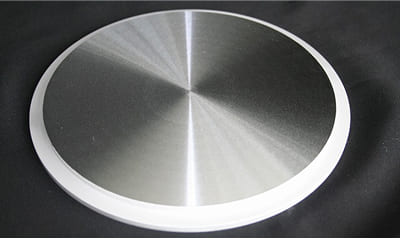

Delivery of a Large Iridium Crucible to Fukuda Crystal Laboratory Co., Ltd.

Furuya Metal manufactured and delivered a large iridium crucible with a diameter of 330 mm to Fukuda Crystal Laboratory Co., Ltd.

Made from high-melting-point iridium, the crucible was used in the Czochralski (CZ) method for growing large sapphire crystals, a process that operates at approximately 2,040 °C.

This achievement contributed to advancements in large-scale crystal growth and the successful launch of related business operations.

2013

Establishment of Furuya Metal Americas Inc.

Furuya Metal established Furuya Metal Americas Inc.in Manchester, New Hampshire, as its second wholly owned overseas subsidiary.

By setting up a local base in North America—one of its most important export markets after Asia—the company strengthened its ability to serve global customers and expand its international business.

Enhancing PGM Recycling Capabilities at the Tsuchiura Plant

A new melting furnace building was constructed at the Tsuchiura Plant, equipped with a state-of-the-art dry furnace for recycling platinum group metals (PGMs).

This upgrade improved the efficiency and recovery rate of precious metals, even from materials containing very small amounts of PGMs.

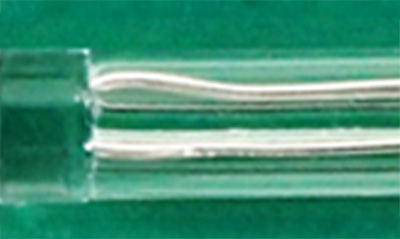

Launch of Iridium–Rhodium Alloy Thermocouples

Furuya Metal launched iridium–rhodium alloy thermocouples capable of measuring ultra-high temperatures exceeding 2,000 °C.

These products support precise temperature control in demanding environments such as semiconductor and LED manufacturing, contributing to the advancement of next-generation technologies.

2014

World’s First Iridium Alloy Tools for Friction Stir Welding (FSW)

Furuya Metal became the first company in the world to commercialize iridium alloy tools for Friction Stir Welding (FSW).

These innovative tools feature exceptional high-temperature strength, enabling the welding of metals with melting points above 2,600 °C, such as molybdenum (2,623 °C) and titanium—materials previously impossible to join using conventional FSW tools.

This groundbreaking development opened new possibilities for high-performance materials processing.

Construction of a Catalyst Building at the Tsuchiura Plant

To expand its recycling and production capabilities, Furuya Metal constructed a new catalyst building at the Tsuchiura Plant dedicated to the mass production of ruthenium-based catalysts.

Together with the dry furnace introduced in 2013, the new facility completed a fully integrated recycling system—enabling the company to process high-purity platinum group metal (PGM) powders into compounds and catalysts, then recover, refine, and reuse them from spent materials.

Selected as One of METI’s Global Niche Top 100 Companies

Furuya Metal was honored to be selected by Japan’s Ministry of Economy, Trade and Industry (METI) as one of the Global Niche Top 100 Companies.

As the only manufacturer specializing in industrial precious metal products to receive this recognition, the company was commended for its technological leadership and global market presence—holding over 60% share in iridium crucibles and 30% in ruthenium targets.

Furuya Metal’s end-to-end capabilities—from procurement and refining to processing and recycling of platinum group metals—continue to support industries worldwide with high-quality, high-value materials.

2015

Mass Production Technology Established for FT-eco Catalysts

Furuya Metal successfully established mass production technology for its proprietary FT-eco catalyst, which efficiently decomposes ethylene (C₂H₄)—a gas that accelerates the spoilage of fruits and vegetables—even at low temperatures.

While conventional catalysts required temperatures of 200 °C or higher to achieve decomposition, the FT-eco catalyst operates effectively in environments ranging from below freezing to 30 °C, converting ethylene into water (H₂O) and carbon dioxide (CO₂).

This represented a breakthrough in low-temperature catalytic performance.

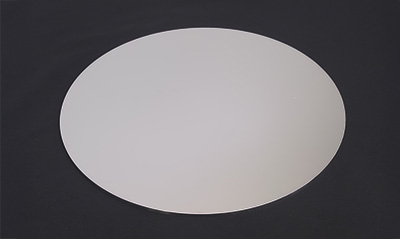

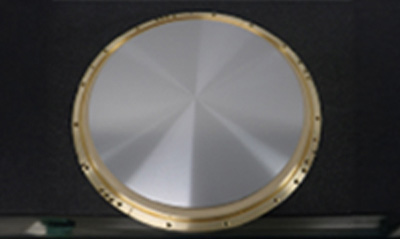

Development of Ultra-High-Purity Melted Ruthenium Targets for STT-RAM

In response to the growing demand for next-generation memory devices, Furuya Metal developed melted ruthenium targets for STT-RAM (Spin Transfer Torque Random Access Memory)—a technology requiring exceptional material purity for electrode components.

The company achieved an exceptionally high 99.999% purity level (five nines), positioning these targets among the highest-purity ruthenium materials available.

2016

Launch of R-SP (Reinforced Thermocouple)

Furuya Metal introduced R-SP, a reinforced R-type thermocouple offering approximately twice the strength of conventional models.

This enhanced durability allows for a longer service life even in high-temperature environments.

The name “R-SP” combines “R”, denoting the R-type thermocouple, with “SP”, derived from Stripe Pattern—which refers to the metal’s unique internal structure—and Special.

Introduction of the Fourth SPS Unit

To meet the growing demand for large ruthenium sputtering targets used in next-generation semiconductor applications, Furuya Metal installed its fourth SPS (Spark Plasma Sintering) system.

This large-scale unit expanded the company’s production capabilities, enabling the manufacture of larger, high-density targets.

2019

Establishment of mass production technology for solid-solution nanoalloys

In collaboration with a research group at Kyoto University, Furuya Metal jointly developed an innovative technology that enables the efficient mass production of nanoscale alloys—something that had previously been extremely difficult to achieve.

This breakthrough allows for the formation of uniform alloy particles as small as 1 nm, significantly enhancing their catalytic performance. The technology is expected to be applied in catalysts for exhaust gas purification and various chemical processes.

By enabling the creation of alloy catalysts efficiently through a single integrated process—previously requiring multiple steps—it represents a major advancement poised to meet growing industrial demand.

Development of FQ (embedded) thermocouples

Furuya Metal developed the FQ (embedded) thermocouple by embedding the sensor directly into quartz, enabling faster temperature measurement with improved response speed and sensitivity compared to conventional models.

The miniaturized design also allows accurate temperature measurement even in restricted spaces.

Development and shipment of large ruthenium targets for next-generation semiconductor wiring

In the semiconductor sector, sputtering targets are essential for forming wiring and electrodes.

Furuya Metal successfully developed and began shipping large, high-density, high-purity ruthenium targets optimized for next-generation semiconductor applications.

2020

Establishment of Furuya Eco-Front Technology Co., Ltd.

Furuya Eco-Front Technology Co., Ltd. was established to develop, manufacture, sell, and export environmental products that utilize FT-eco® catalysts. These include applications for freshness preservation, as well as antifungal and antibacterial technologies that contribute to a more sustainable and hygienic environment.

Selected again for the Global Niche Top 100 Companies by the Ministry of Economy, Trade and Industry (METI)

Furuya Metal was once again selected for Japan’s Global Niche Top 100 Companies (2020 edition) by the Ministry of Economy, Trade and Industry (METI), following its earlier recognition in 2014.

The selection highlighted the company’s success in applying its advanced iridium processing technologies to new industries and products with strong market shares, as well as its commitment to raw material recycling and the establishment of a stable global supply system.

Joint venture agreement between Anglo Platinum Marketing Limited and Furuya Eco-Front Technology Co., Ltd.

2021-Third stage: Toward the next leap forward — creating a future no one else dares to pursue

In 2023, Furuya Metal achieved a major milestone with its listing on the Tokyo Stock Exchange Prime Market — a long-standing company goal.

Building on this success, the company continues to anticipate emerging needs in step with the changing times, focusing on advanced research and development to further strengthen its technological and corporate value.

Through the creation of new markets and businesses, Furuya Metal remains committed to delivering new value and contributing to a more sustainable future.

2021

Establishment of Furuya Eco-Front Technology (Shanghai) Co., Ltd.

Development of high-grade ruthenium alloy targets for EUV lithography

Furuya Metal developed high-grade ruthenium alloy targets for EUV (Extreme Ultraviolet) lithography, establishing an ultra-high-purity target manufacturing technology that minimizes impurities to the utmost limit through its proprietary melting process.

EUVリソグラフィ(Extreme Ultraviolet EUV lithography is an essential semiconductor manufacturing technology that enables further device miniaturization.

2022

Transition from JASDAQ (Standard) to the Tokyo Stock Exchange Standard Market

Launch of mass production and shipment of AlSc targets

As the electronics industry advances toward further miniaturization and functional enhancement, Furuya Metal began mass production and shipment of AlSc (aluminum–scandium) alloy targets.

These materials offer excellent electrical conductivity and stability, marking the company’s first mass-produced non-precious-metal sputtering target.

2023

Transition from the Tokyo Stock Exchange Standard Market to the Prime Market

In December 2023, Furuya Metal transitioned from the Standard Market to the Prime Market of the Tokyo Stock Exchange, marking a significant step forward in its evolution as a publicly accountable and globally competitive company.

Launch of a quartz processing line in Building C at the Tsukuba Plant

Amid the expansion of the semiconductor market and rising demand for quartz components used in semiconductor manufacturing equipment, Furuya Metal installed a new quartz processing line in Building C at the Tsukuba Plant.

This addition enabled production at both the Chitose and Tsukuba Plants, establishing a dual-site production structure with built-in business continuity planning (BCP) considerations.

2024

Merger with Nano Cube Japan Co., Ltd.

Furuya Metal merged with Nano Cube Japan Co., Ltd., a company specializing in the manufacturing, sales, and contract development of nanoparticles through microchemical processes.

This merger further advanced Furuya Metal’s development of mass production technology for nanoalloys.

2025

Establishment of a sales base in Shanghai

Acquired all shares of Furuya Advanced Environmental Technology (Shanghai) Co., Ltd., a joint venture between Furuya Metal and Furuya Eco-Front Technology Co., Ltd., making it a wholly owned subsidiary of Furuya Metal.

The company was renamed Furuya Nonferrous Metals (Shanghai) Co., Ltd. and now serves as Furuya Metal’s sales base in the People’s Republic of China.