Commitment to Analytical Excellence

Trusted Quality—built on the foundation of analytical expertise

At Furuya Metal, our Analytical Division serves as the cornerstone of high-grade precious metal production. By continually advancing our analytical technologies, we ensure the precise detection and evaluation of even trace-level elements—maintaining uncompromising standards of quality and reliability.

With decades of accumulated expertise in precision analysis, our mission is to guarantee that every product and recovered material achieves the highest levels of purity, consistency, and performance. Analytical science is not merely a support function for us—it is the foundation of trust that upholds our entire manufacturing process.

Moreover, our analytical capabilities play a vital role in driving innovation, supporting the development of new products and technologies that evolve in step with global trends and industrial progress.

Analytical facilities

Tsukuba Plant

Furuya Metal produces precious metals of exceptional purity, including ultra-high-purity materials exceeding 99.999% (5N). To ensure this level of quality, we have established an in-house analytical system capable of detecting impurities at the parts-per-billion (ppb) level.

Our analytical framework is supported by the following capabilities and practices:

- Advanced instrumentation: Trace analysis is conducted using ICP-MS and GD-MS, covering nearly the entire periodic table.

- Proprietary correction methods: Elemental interferences are effectively compensated to ensure consistent and reliable quantitative data.

- Rigorous analytical protocols: Company-established procedures guarantee high reproducibility and traceability.

- By working closely with production lines, an integrated feedback loop enables daily, real-time analytical insights to the manufacturing process.

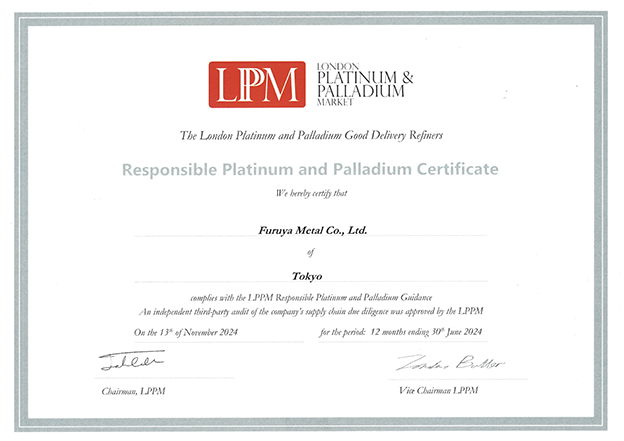

Furuya Metal has also obtained Good Delivery accreditation from the London Platinum and Palladium Market (LPPM), confirming that our analytical and production standards meet globally recognized benchmarks.

For further information, please refer to the section “LPPM Accreditation.”

Tsuchiura Plant

Delivering both precise precious metal assay and high-efficiency resource recovery, the Tsuchiura Plant also serves as a key manufacturing base for iridium (Ir) and ruthenium (Ru) compounds, supporting a wide range of industrial applications.

Key functions and features include:

- Assay and evaluation of recovered scrap, catalysts, and spent products

- Extensive expertise in high-purity refining and recycling of precious metals

- Environmentally responsible recycling processes and advanced emission control systems

- In-house production lines for iridium and ruthenium compounds used in semiconductor and chemical industries

- Integrated operations linking manufacturing with on-site analysis and quality verification to ensure product reliability

Guided by the mission of “returning limited resources to society in a renewed and valuable form,” the Tsuchiura Plant plays a central role in promoting a sustainable, resource-circulating society.

Analytical process flow

1.Sample Acceptance

Samples are received under a strict management and traceability system to ensure integrity and security.

2.Pre-Treatment (1)

Samples are dissolved in acid using equipment designed with the highest safety standards, enabling accurate analysis of precious metal components.

3.Pre-Treatment (2)

Samples that cannot be dissolved by acid are fully decomposed using alkaline fusion or other specialized methods.

4.Gravimetric Chemical Analysis

PGM oxides are reduced in a hydrogen reduction furnace, and the resulting residue is weighed to determine precise analytical values.

5.Instrumental Analysis

Trace elements are quantified with high precision using instruments such as ICP-OES and GD-MS.

6.Review of Analytical Results

All analytical results undergo careful examination and multi-person verification to ensure accuracy and reliability.