Iridium Processing Technology

Iridium (Ir) possesses properties unmatched by any other metal—extraordinary corrosion resistance, heat resistance, and mechanical strength, even at extremely high temperatures. Owing to these exceptional characteristics, iridium is widely used in applications that demand reliability under the most severe conditions, including single-crystal growth, electrolytic electrodes, aerospace components, medical devices, and next-generation energy systems such as green hydrogen production.

However, iridium’s intrinsic hardness and brittleness make it extremely challenging to process. Its fabrication requires not only advanced technology but also deep metallurgical expertise.

At Furuya Metal, our technological strength lies in the integration of two advanced capabilities:

- Melting and processing technologies, which enable the transformation of mined iridium powder into precision-engineered products; and

- Recycling and purification technologies, which recover used iridium materials and refine them into ultra-high-purity metal.

By combining these two proprietary processes, we achieve the consistent production of iridium components with exceptional purity, dimensional precision, and performance stability.

Only a select few manufacturers worldwide possess both of these technologies—and Furuya Metal stands among them as a global leader in iridium processing.

Furuya Metal’s Iridium products

By fully integrating our advanced processing and refining technologies, Furuya Metal supplies a comprehensive range of iridium products designed to meet the demanding requirements of cutting-edge industrial and scientific applications.

Our product lineup includes:

- Iridium crucibles for oxide single-crystal growth—essential for producing optical, electronic, and power device materials;

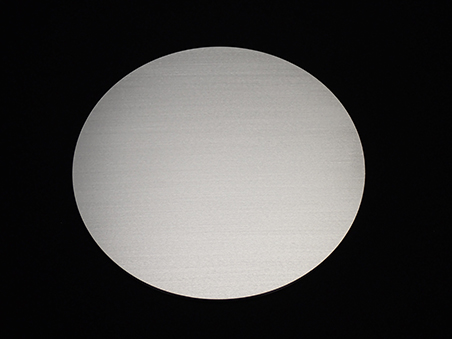

- High-purity, high-precision iridium targets, used in next-generation semiconductor memory devices;

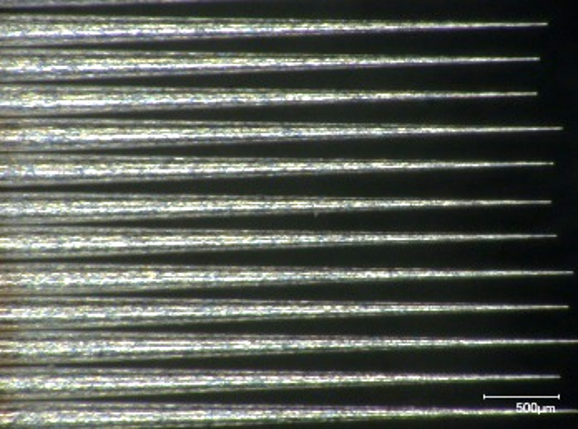

- Ultra-thin iridium sheets, as fine as 0.1 mm, enabling applications that require extreme precision and thermal stability;

- Iridium–rhodium thermocouples, capable of accurate temperature measurement up to approximately 2,000 °C in oxidizing atmospheres;

- Iridium-based compounds employed in OLED phosphorescent materials, electrolytic electrodes, and catalysts for water electrolysis in hydrogen production.

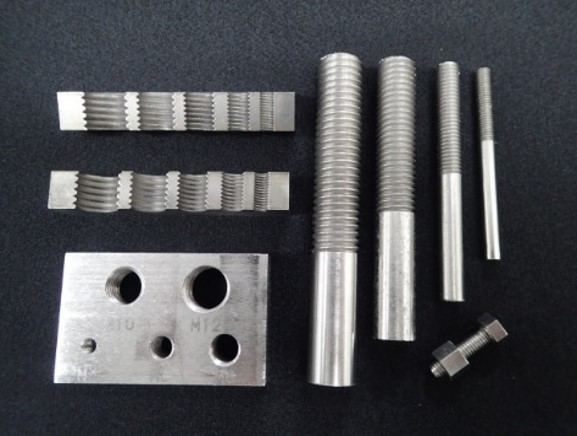

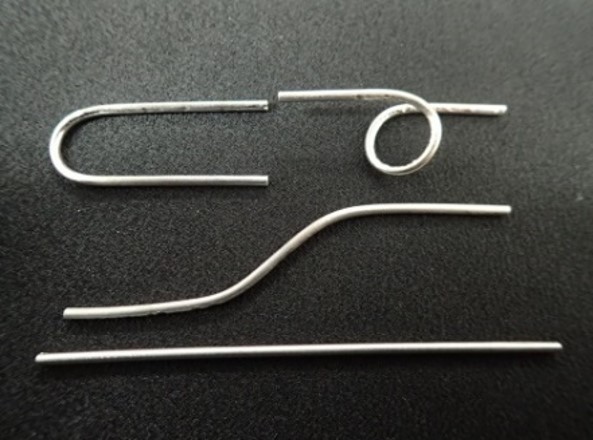

In addition, Furuya Metal leverages its long-cultivated expertise in precision processing and microfabrication, enabling the development and manufacture of high-performance iridium components with unmatched dimensional accuracy and reliability.

Iridium processing technology

During the forging and rolling of iridium, precise temperature control is maintained to produce sheets with exact, predetermined dimensions. These sheets then undergo a sequence of precision machining processes—including cutting, shaping, and assembly—to form individual components, which are subsequently finished into final products through advanced welding techniques.

Our welding operations combine state-of-the-art automation with the craftsmanship of highly skilled technicians. Because iridium has an exceptionally high melting point—exceeding 2,400 °C—its welding requires specialized methods and deep metallurgical expertise far beyond those used for other metals. Furuya Metal takes pride in its superior welding capabilities, refined through decades of experience and innovation.

Beyond welding, we possess a comprehensive suite of precision fabrication technologies, including rolling, wire electrical discharge machining (EDM), fine wire drawing, and crystallization processes for iridium compounds.

For iridium-based compounds, our dedicated production facilities achieve a manufacturing capacity of approximately seven metric tons per year (metal equivalent), ensuring both industrial-scale supply and exceptional purity.

Iridium melting technology

As noted earlier, iridium has an exceptionally high melting point—exceeding 2,400 °C—which necessitates the use of specialized equipment such as plasma melting furnaces for its processing. A plasma melting furnace operates with an ultra-high-temperature plasma exceeding 5,000 °C, enabling the vaporization and removal of residual impurities from the iridium.

At Furuya Metal, we employ a double melting process to produce high-purity iridium ingots. In recent years, we have also introduced electron beam (EB) melting furnaces, which achieve even higher temperatures and allow for further refinement and purification. Through the combined application of these advanced melting techniques, Furuya Metal supplies iridium products of exceptional purity, consistency, and reliability—meeting the stringent demands of advanced industrial applications.

Recycling and high-purification technology

Furuya Metal was among the first in Japan to establish a comprehensive recycling system for iridium. Iridium raw materials are primarily sourced from South Africa; however, they often contain significant levels of impurities, and certain batches cannot be used in their natural state. Each batch is analyzed using our in-house analytical instruments, and materials with a purity below 99.95% are directed to our refining line for further purification.

During this high-purification process, base metals and other Platinum Group Metals (PGMs)—including ruthenium (Ru), platinum (Pt), palladium (Pd), and rhodium (Rh)—are quantitatively removed, resulting in iridium products of exceptional quality and consistency. Because impurities critically affect not only the manufacturing process, durability, and service life of iridium crucibles, but also the crystal quality of the single crystals grown within them, impurity minimization is paramount.

Our recycling and refining technologies form an indispensable foundation for achieving ultra-high-purity iridium and ensuring the stable production of high-quality iridium components. Furthermore, these technologies enable the recovery and purification of iridium even from low-content sources—such as refractory materials and spent electrodes used in single-crystal growth furnaces—thereby contributing to the sustainable circulation of this rare and valuable resource.