Ruthenium Processing Technology

Ruthenium (Ru) is a precious metal renowned for its exceptional corrosion resistance and catalytic properties. It is utilized across a wide range of industrial fields, including electronic materials for HDDs (Hard Disk Drives) and semiconductors, as well as corrosion-resistant coatings and catalyst technologies.

At the same time, ruthenium’s intrinsic properties—high hardness, high melting point, and brittleness—make it one of the most challenging metals to process.

Furuya Metal has developed a proprietary recycling technology that creates a closed-loop system for the high-precision processing and refining of this hard-to-machine metal, achieving both technological advancement and sustainable resource utilization.

Furuya Metal’s Ruthenium products

By integrating our advanced processing and refining technologies, Furuya Metal supplies a diverse range of high-quality ruthenium products, including ruthenium sputtering targets (ruthenium targets) and ruthenium compounds.

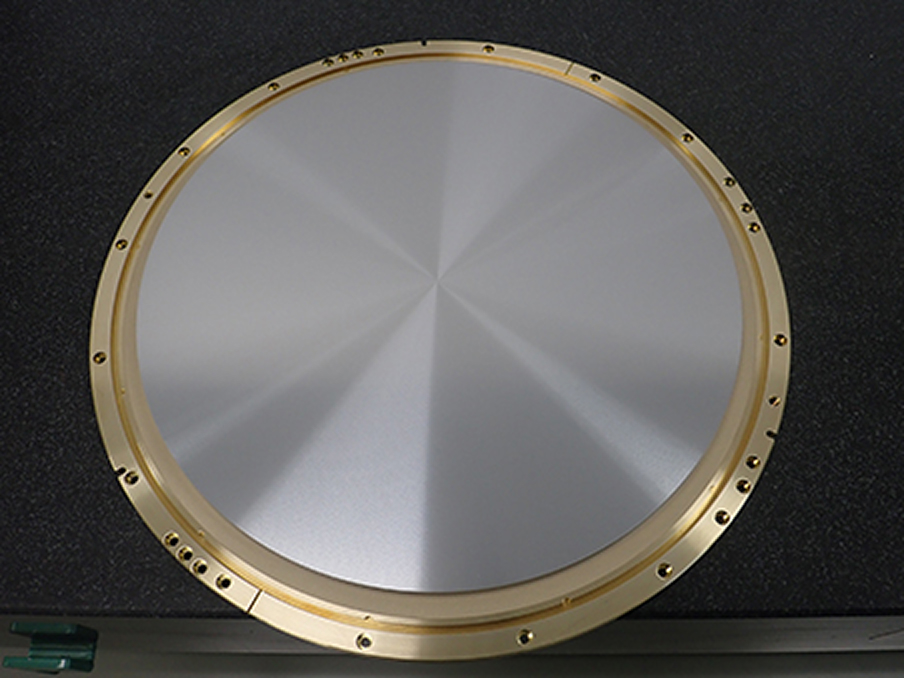

Ruthenium targets are primarily used as a key material in the recording layers of HDDs—a critical foundation for increasing storage capacity—and are also expected to serve as core materials for next-generation semiconductors and memory devices. We provide both pure ruthenium and ruthenium alloy targets, offering large-diameter targets as well as ultra-high-purity targets (99.999%, 5N) manufactured through our proprietary melting and refining technologies, which minimize impurity content to the utmost limit.

Through the combined application of sintering and melting technologies, we adapt flexibly to specific requirements and end-use applications, consistently delivering products of the highest quality—a defining strength of Furuya Metal.

In addition, we supply high-purity ruthenium compounds used in catalysts and electrodes, with a production capacity of approximately 30 tons per year (metal equivalent).

Leveraging our advanced purification technologies, we also produce ultra-high-purity ruthenium powders (99.999%, 5N) characterized by uniform particle size and minimal impurities, meeting the demanding requirements of cutting-edge electronic and chemical applications.

φ444 mm, 4N

Processing technology for ruthenium targets

Due to ruthenium’s extreme difficulty to process, Furuya Metal primarily manufactures its targets using the Spark Plasma Sintering (SPS) method. This technique enables bulk forming through near net shape molding without compromising the intrinsic properties of high-purity ruthenium powder.

We operate multiple large-scale SPS systems—among the largest in Japan—and leverage high-speed sintering technology to achieve efficient, high-quality production.

Our SPS systems are also capable of fabricating a wide variety of metallic and composite materials with exceptional efficiency. They can process not only single-metal powders, but also alloy powders, composite powders of high- and low-melting-point metals, and even hybrid metal–ceramic compositions, thereby accommodating a broad spectrum of material configurations and application requirements.

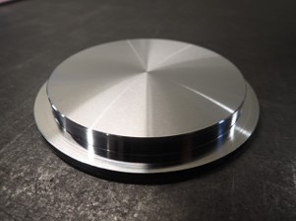

Monolithic sputtering target

Despite ruthenium’s extreme hardness and brittleness, we manufacture monolithic, backing plate–free targets using a range of specialized processing techniques.

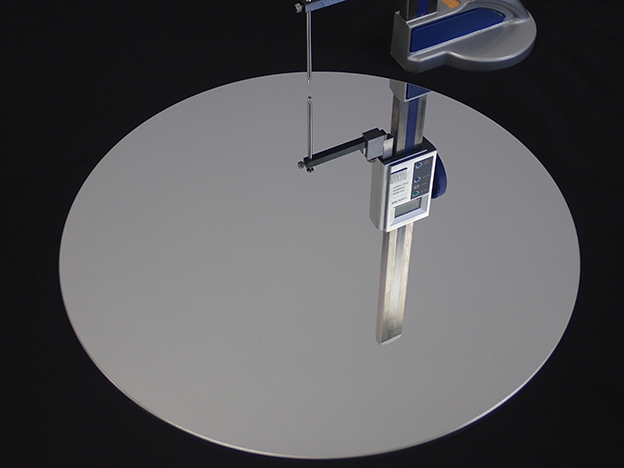

Sintered sputtering target (Mirror finish)

To minimize initial particle generation and shorten pre-sputtering time, we have developed a sintered target with an ultra-smooth surface (Ra < 0.1 μm), achieved through a specialized polishing process.

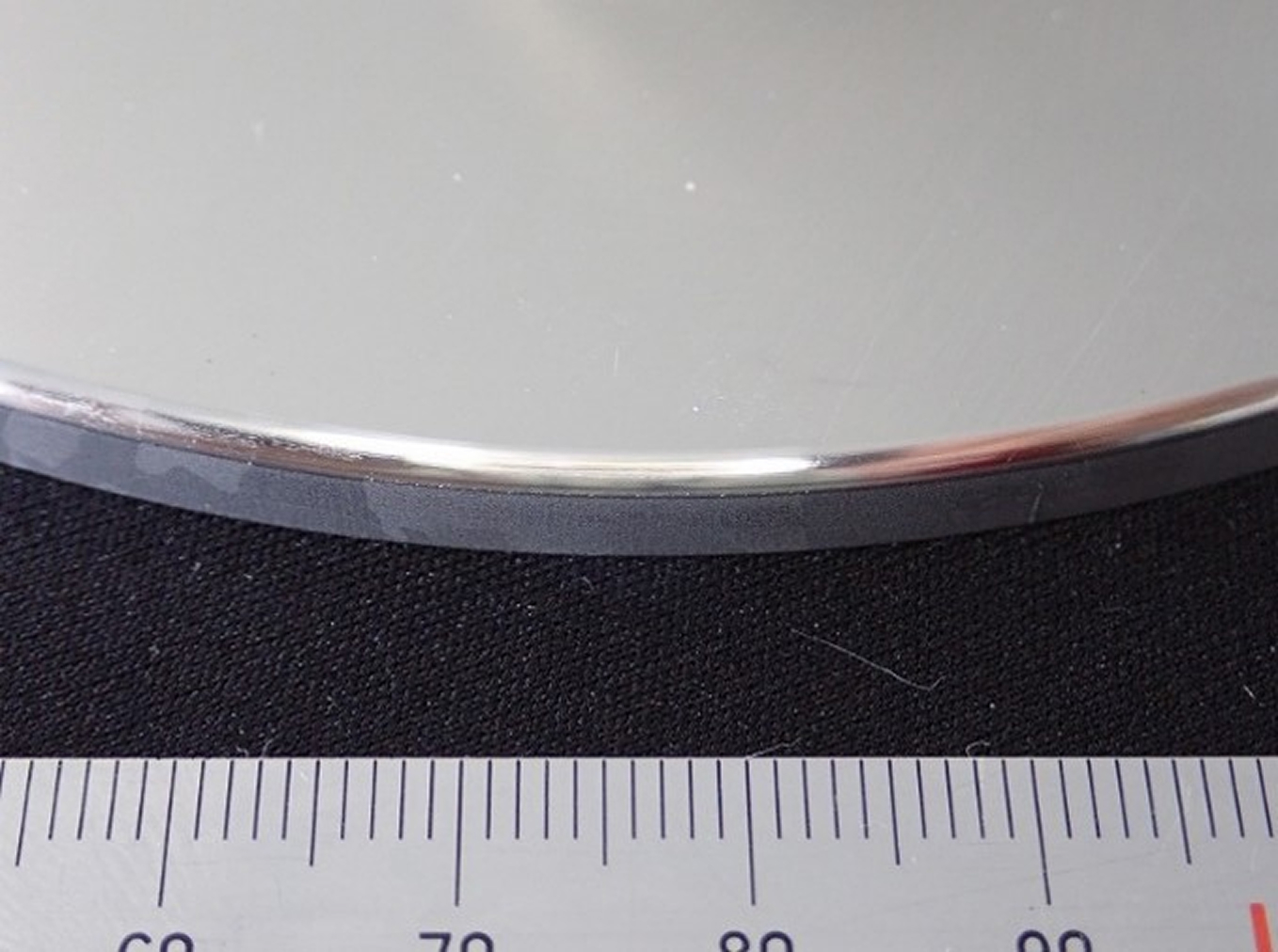

Melted sputtering target (R-edge machining)

To prevent arcing at the target edge, the product features R-shape edge processing. The machining method and conditions have been carefully optimized to avoid chipping or grain drop-out during processing.

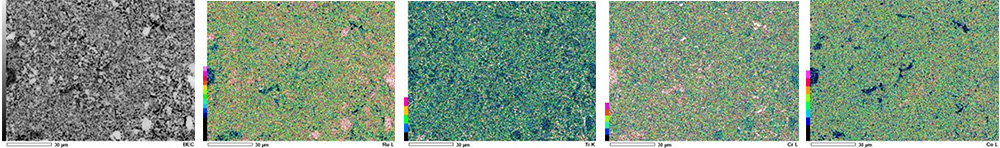

Ultrahigh dispersion material

Using our proprietary powder compounding technology, we produce ultrahigh dispersion powders.

By applying high-speed sintering via the SPS method, we fabricate bulk materials that maintain a highly dispersed structure while effectively suppressing grain growth.

This approach enables highly dispersed sintered structures in both ruthenium–metal and ruthenium–ceramic systems.

Recycling and high-purification technology

Furuya Metal was the first company in the world to establish a complete recycling system for ruthenium.

Ruthenium raw materials are typically mined in South Africa, but they often contain significant impurities and, depending on the application, cannot be used in their natural state. These materials are analyzed using our in-house analytical instruments and then purified through our proprietary recycling system to achieve the required level of purity.

Similarly, various spent products are refined through this system and reborn as high-purity ruthenium. Our purification process enables the quantitative reduction of base metals and other platinum-group metals (PGMs), ensuring a stable and continuous supply of high-quality ruthenium products.

Furuya Metal’s recycling technology is critical for industries where even trace impurities can affect performance—particularly in storage and semiconductor applications.

Moreover, our technologies allow the recovery and refinement of ruthenium from low-content sources, such as disposable shields used in sputtering equipment and spent catalysts, thereby contributing to the sustainable recycling of this rare and valuable resource.