Innovation begins here — shaping the future no one has imagined

Advanced Powder Sputtering Technology:

Driving the Creation of Next-Generation Materials

When you hear the word “coating (thin film deposition),” what comes to mind?

For many, it might be technologies that protect human skin, preserve car paint, or keep buildings looking new against ultraviolet rays, rain, and dust. Because of this protective role, coating technologies are widely used across many industries.

But coatings do more than just protect. They can also give existing materials entirely new functions.

At Furuya Metal, we’ve taken this further with our advanced powder sputtering technology, driving the development of next-generation electronic materials.

From sputtering targets as the starting point

The technique of applying a coating (thin film) to a material to give it new functions has been around for a long time. Electroplating, for instance, not only provides protection but also enhances electrical conductivity. Similarly, urethane and water-based coatings can add properties such as breathability or water solubility to materials.

These kinds of wet coating technologies, which rely on liquid processes, are widely used across many industries. However, they are not suitable for high-performance electronic materials that require ultra-precise thin films—formed at the atomic or molecular level—while also avoiding any contamination.

For such applications, a process known as sputtering (vacuum thin-film deposition) makes it possible to achieve the required level of precision.

Sputtering technology is used not only in electronic materials but also in everyday products, such as aluminum-coated films for food packaging that help prevent oxidation.

Recognizing its importance, Furuya Metal has made precious-metal-based sputtering targets—essential for producing high-performance electronic materials—one of its core products. Through this, we continue to support the advancement of semiconductors, LCDs, OLEDs, and other key technologies that power modern electronics.

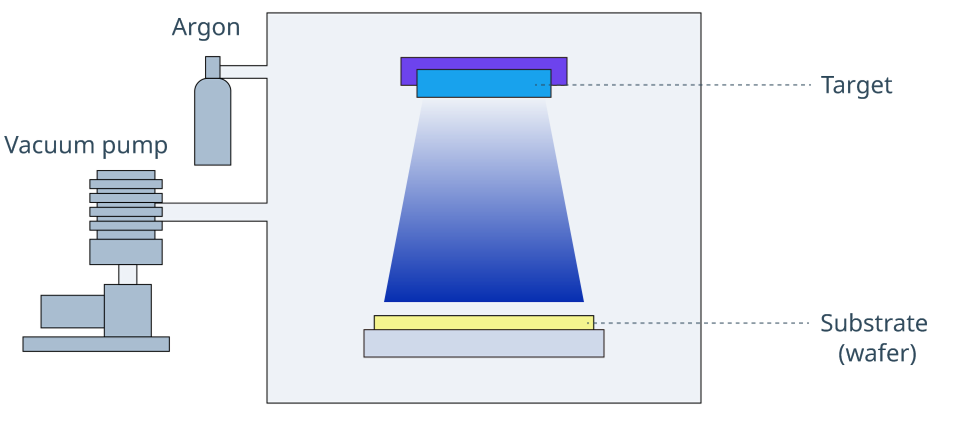

Mechanism of sputtering technology

Inside a vacuum chamber, argon ions are accelerated toward the sputtering target. When they collide with the target, atoms and molecules are ejected from its surface. These particles then travel through the chamber and deposit onto substrates, such as silicon wafers or glass, forming a thin film.

Forming nano-level films on powders

Sputtering is essential for the evolution of high-performance electronic materials. As demand for ever-greater performance accelerates, Furuya Metal’s powder sputtering technology—refined for over 20 years—is attracting fresh attention.

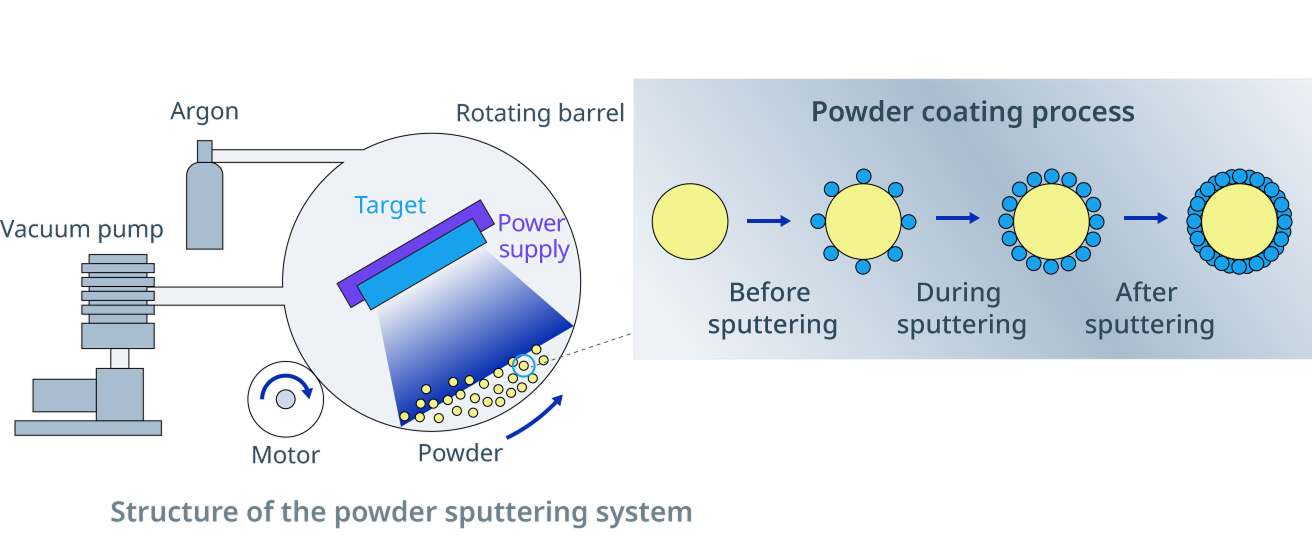

Unlike conventional sputtering, which is limited to flat substrates such as silicon wafers, glass, or films, powder sputtering creates nano-scale thin films directly on fine powders. It can deposit multiple elements at once to form alloy films or build complex, multi-layered structures with customized compositions.

This capability has enabled breakthrough products with unprecedented functionality, from electronic components and batteries to catalysts and even cosmetic raw materials. More recently, it has emerged as a promising technique for developing electrode materials in all-solid-state batteries, known for higher safety and performance than conventional lithium-ion batteries.

Recognizing this potential early, Furuya Metal began foundational research in 2005, fostering innovation within a culture that embraces bold challenges. Today, the company provides contract thin-film deposition services that support diverse compositions and structures—helping customers explore next-generation materials across electronics and beyond.

Mechanism of powder sputtering technology

Plasma is generated above the target to coat powder surfaces while the rotating barrel disperses the particles for uniform coating.

Microscopic image of powder coated via sputtering technology

Example: A resin particle approximately 3 μm in diameter, coated with a silicon film just 5 nm thick.

Expanding the contract thin-film business with proprietary technologies

Furuya Metal began as a developer and manufacturer of sputtering target materials. So why enter the contract powder sputtering business? The answer lies in our unique proprietary technologies.

Building on our Chemical Business, we produce high-purity Platinum Group Metals (PGMs) and their compounds. This gives us not only deep expertise in precious metal powders but also proven production methods for mass-producing PGM sputtering targets with consistent quality.

By combining these strengths, we began exploring powder sputtering—then an emerging field for high-performance electronic materials and catalysts. In 2005, we introduced a “barrel-type” powder sputtering system for early-stage research. Over time, improvements in target materials, particle agitation inside vacuum chambers, and other processes allowed us to steadily expand our customer base.

By 2010, we had independently developed equipment capable of alloy film formation and multi-layer deposition using ternary sputtering, along with several prototype systems featuring alternative mechanisms. After years of refinement, a new system was launched in 2022 with an innovative powder agitation method, enabling the stable mass production of higher-quality powder-sputtered materials.

Since then, our team has consistently contributed to industry progress by providing co-development support, facilitating equipment enhancements, and expanding production capacity to address the changing performance needs of our customers.

Leveraging our experience, know-how, and data

To date, Furuya Metal has produced approximately 4,000 prototype samples through contract powder sputtering. Following extensive refinement and scaling efforts, we are now moving toward mass production.

The technology offers a wide range of potential applications across sectors including automotive, electronics, industrial products, and consumer goods.

Looking forward, we will continue to draw on the extensive experience, expertise, and data accumulated through these developments. By doing so, we aim to equip our customers’ new materials with the full power of sputtering technology, delivering functionalities that surpass conventional limits.