FURUYA

HISTORY

Pushing the boundaries of what’s possible

This is the untold story of perseverance—

The journey of Takahito Furuya, founding member and

current president of Furuya Metal.

From jewelry to industrial precious metals

A new beginning born in a family garage

From jewelry to industrial precious metals

The origins of Furuya Metal trace back to Furuya Shoten, a small family business founded by Takahito Furuya’s father, Masanori Furuya, which specialized in the sales and production of precious metal jewelry. When the business was later incorporated as Furuya Metal Co., Ltd., Takahito was invited to join the company with a bold challenge:

“Why don’t you take the lead on the front lines of sales?”

Using his natural talent for sales, Takahito worked tirelessly to expand existing accounts and develop new customers. However, as a small latecomer in the jewelry industry, Furuya Metal struggled to generate stable profits. Determined to find a new path forward, Takahito advised his father, then president, to shift the company’s focus to industrial precious metals. The company began handling these metals as a specialized trading firm.

The first step toward becoming a manufacturer of industrial precious metals

Even after changing its business domain, new challenges quickly emerged. As Furuya Metal became more established in the industrial sector, it began to compete directly with its own suppliers—the metal producers—for the same client base. When business relationships started to strain, Takahito made a bold decision: Furuya Metal would establish its own manufacturing capabilities.

The company had no factory, no equipment, and no technical know-how. What caught Takahito’s eye was the garage attached to his father’s home, which also served as the company’s head office at the time. He asked his father, “Would you sell the car and let me turn the garage into a workshop?”

Moved by his son’s determination, Masanori agreed. The family garage was transformed into a small factory, becoming the starting point of Furuya Metal’s journey in manufacturing.

Story1

Persuading an engineer through relentless persistence

Even after securing a place for manufacturing and acquiring equipment, Furuya Metal still lacked what mattered most—an engineer with the necessary expertise. Takahito began production through trial and error, but progress was limited. Determined to move forward, he finally tracked down a retired veteran craftsman, once known for his exceptional skill.

The man had left the factory years earlier and had been in a completely different line of work for seven years. His initial response was firm: he had no intention of returning to manufacturing. For Takahito, having such a craftsman was vital to the company's survival.

Describing himself as “relentlessly persistent,” Takahito refused to give up after one or two rejections. Through unyielding persuasion, he ultimately won the craftsman’s cooperation—an act that became a turning point in Furuya Metal’s early manufacturing journey.

Taking on rare metals difficult to handle in Japan

Expanding production capacity to meet growing demand

In the late 1970s to 1980s, when home video recorders (VTRs) were first introduced to Japan and competition among manufacturers intensified, Furuya Metal began producing standard crucibles*—a development that marked a fortunate turning point for the company.

To meet industry demand for head materials used in VTRs, Furuya Metal developed special pointed-bottom crucibles, a shape that was technically difficult to manufacture at the time.

Through the successful development and sales of these specialized crucibles, the company earned the trust of major home electronics manufacturers.

As orders increased, production in the small garage could no longer keep up, prompting Furuya Metal to establish a second plant to expand production capacity.

* Crucibles are heat-resistant containers used for chemical analysis and high-temperature processing.

Repairing an iridium crucible under desperate circumstances

A challenge that tested the company’s determination.

Following the successful development of standard crucibles, Furuya Metal began receiving numerous technical inquiries from manufacturers.

Among them was one particularly difficult request:

“Can you repair a used iridium crucible?”

At that time, no company in Japan had the capability to handle iridium (Ir), and production and repair depended entirely on overseas suppliers. However, domestic manufacturers wanted to reduce costs and complete the process within Japan.

With this in mind, four damaged crucibles were entrusted to Takahito and his team. They tried heating them with a burner, but the iridium did not respond. Overheating risked a steam explosion, making the task extremely dangerous. One after another, three crucibles shattered beyond repair. Driven by a strong desire to fulfill the customer’s request, the team continued experimenting—and finally succeeded in restoring the fourth crucible. It was a moment when sales and engineering became one, united in purpose and spirit.

Becoming president and focusing on iridium and ruthenium

In August 1987, Takahito Furuya was appointed President, becoming the second-generation leader of Furuya Metal. The management team decided he was the right person to lead the industrial precious metal business due to his industry trust and active sales experience.

Determined to make Furuya Metal “an even greater company,” Takahito set forth two key strategies: to pursue challenges no other company would attempt, and to build a solid business foundation by cultivating multiple core pillars.

Central to this vision was his decision to continue investing in iridium and ruthenium (Ru), two precious metals whose future demand was still uncertain. This commitment laid the groundwork for long-term growth and technological leadership.

Story2

Finding opportunity where no one else dares to look

When Takahito obtained information about iridium and ruthenium from a trading company handling foreign settlements for the company, he was captivated. “I had no idea such extraordinary metals existed,” he recalled.

Due to their rarity and processing difficulty, these metals had few practical applications and scarce sales opportunities.

Still, driven by his defiant spirit, Takahito believed that “because no one else is doing it, the potential for growth must be enormous.”

While others would have overlooked such a niche field, he continued pursuing it, forming the foundation for Furuya Metal’s core business.

Responding to scarce resources and growing demand with a new recycling model

Constructing a huge plant that was widely believed to risk the company's future

As demand for VTR components soared during Japan’s economic bubble, the company’s original 330 m² site reached full capacity. As a result, Takahito made the bold decision to construct the Tsukuba Plant, covering 23,000 m². Industry peers warned that this overextension would “surely bring the company down.”

Contrary to those doubts, production continued to expand, and the Tsukuba Plant became the central hub for manufacturing and development.

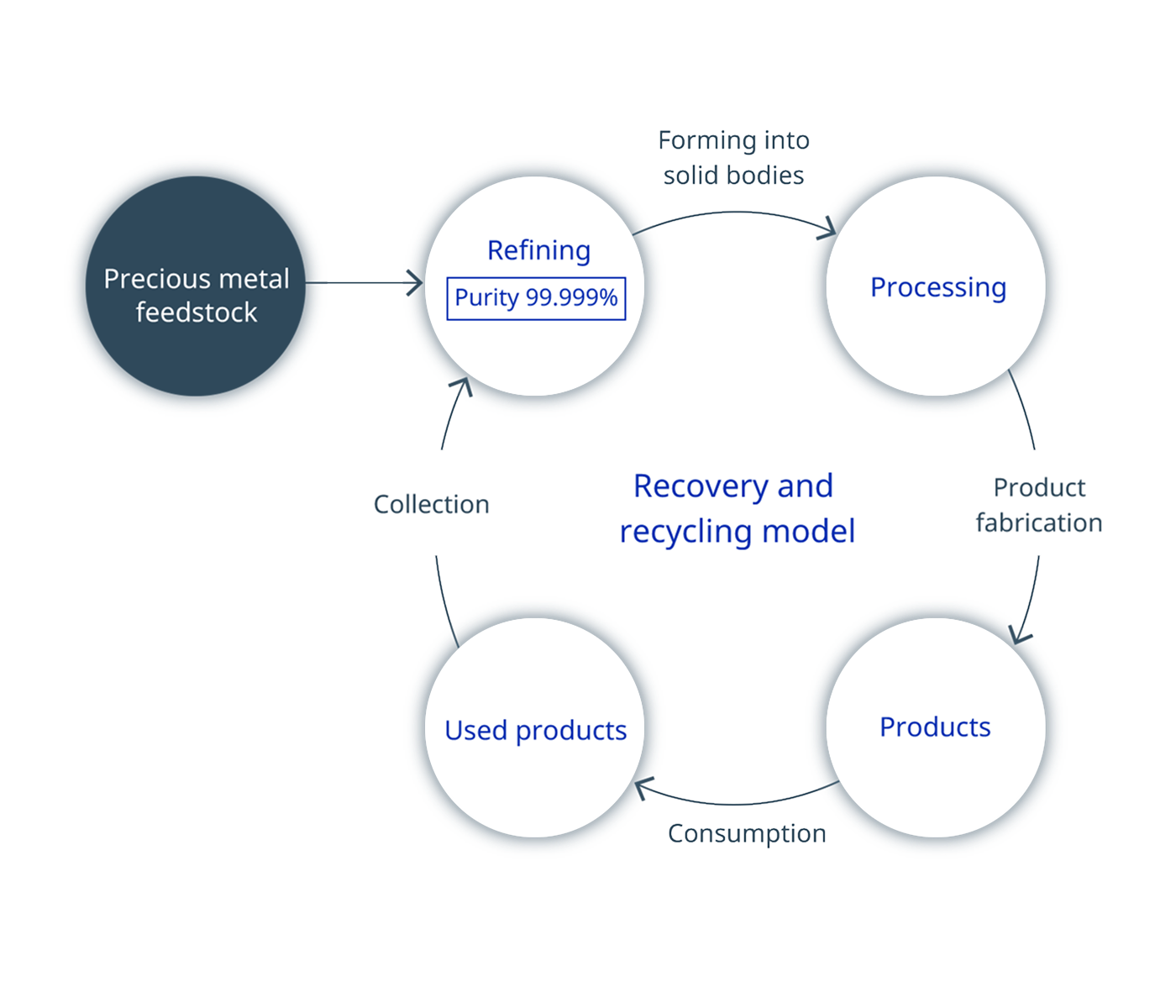

Establishing a closed-loop recycling model for iridium and ruthenium

For a company whose core business revolves around iridium and ruthenium—two of the world’s rarest and most valuable precious metals—ensuring a stable supply has long been both a strategic concern and a major cost factor.

In the 1980s, alongside the launch of crucible production, Furuya Metal began research to develop technology for recovering and refining used products.

Through years of experimentation, the company succeeded in creating an original recycling process capable of extracting specific precious metals from complex, multi-material compounds and refining them to ultra-high purity.

This breakthrough marked a significant step toward sustainable business growth.

Today, Furuya Metal has the capacity to recover approximately 40 tons of ruthenium and 10 tons of iridium per year—a scale nearly equivalent to the world’s total annual production of these metals.

Story3

Turning “no one else does it” into the shortest path forward

At first, Furuya Metal outsourced its recovery and refining operations. However, as demands on efficiency grew, it became clear that bringing these processes in-house was essential to improve both cost and delivery speed.

This shift became possible with the introduction of a plasma melting furnace—an advanced system capable of handling ultra-high-temperature metals such as iridium.

Guided by his conviction that “we never want to do what everyone else is doing,” Takahito Furuya chose the plasma furnace over the vacuum melting systems commonly used by domestic and international manufacturers.

Although the equipment supplier cautioned that it would take “two to three years before full operation,” Furuya’s engineers, through relentless effort and ingenuity, achieved stable operation in just eight months. This led to crucibles of unprecedented quality and precision, giving Furuya Metal a lasting technological edge.

Supporting cutting-edge industries through new applications developed in partnership with customers

Establishing a research and development facility for new technologies

In 1998, Furuya Metal completed a new research and development facility on the grounds of its Tsukuba Plant.

A key goal was to develop thin-film technology, seen as the next growth area after precious metal crucibles.

This initiative led to the creation of APC*, Furuya Metal’s proprietary silver alloy material. APC later became widely used as a reflective and electrode material in optical discs, LCD panels, LEDs, and touch panels.

* APC: A silver alloy target material (Furuya Metal holds the trademark rights for this product name).

Advancing joint research toward new applications

The Tsukuba Research and Development Center, now the company’s core R&D hub, also provides thin-film deposition services for customers.

The precious metal sputtering targets essential to semiconductor manufacturing are developed using technologies unique to Furuya Metal.

These technologies leverage the unique characteristics of metallic materials to enable large-scale manufacturing of high-performance semiconductors, which are integral to advanced sectors such as artificial intelligence and electric vehicles.

At Furuya Metal, sales and engineering teams work closely together to translate customer needs into practical solutions with remarkable speed.

This collaboration lies at the heart of the company’s innovation and growth.

Achieving the long-awaited Prime Market listing and continuing to contribute as a truly public company

A president who has always led by challenging himself first

From just five employees at its founding, Furuya Metal has grown to over 400, including those at its overseas group companies.

In 2006, the company was listed on the JASDAQ Market, becoming Japan’s first manufacturer specializing in industrial precious metals to go public.

For Takahito Furuya, who believed that transforming Furuya Metal from a family-run business into a publicly accountable organization was essential for its future, this marked a deeply meaningful milestone.

In 2023, Furuya Metal realized its long-held goal of listing on the Tokyo Stock Exchange Prime Market, reaffirming its commitment to remain an “eternal venture company” while striving to become the global leader in iridium and ruthenium.

Continuing to take on challenges that no one else dares to—and constantly pioneering new frontiers—this spirit of Takahito Furuya has become the very DNA of Furuya Metal, carried forward by every employee.