Environmental Management System

Basic approach

In line with our Environmental Policy, Furuya Metal has established and maintains an environmental management system based on the international standard ISO 14001.

We are committed to continuously improving the effectiveness of this system in both implementation and operation. Through this framework, we ensure compliance with environmental laws and regulations, identify and assess the environmental impacts of our business activities and products, and work to reduce our overall environmental footprint.

Our production sites—Tsukuba Plant, Tsuchiura Plant, and Chitose Plant—each holds ISO 14001 certification, valid as of 2025.

Since 2009, Furuya Metal has operated an Integrated Management System combining Environmental Management (ISO 14001) and Quality Management (ISO 9001), promoting more efficient and effective implementation across both systems.

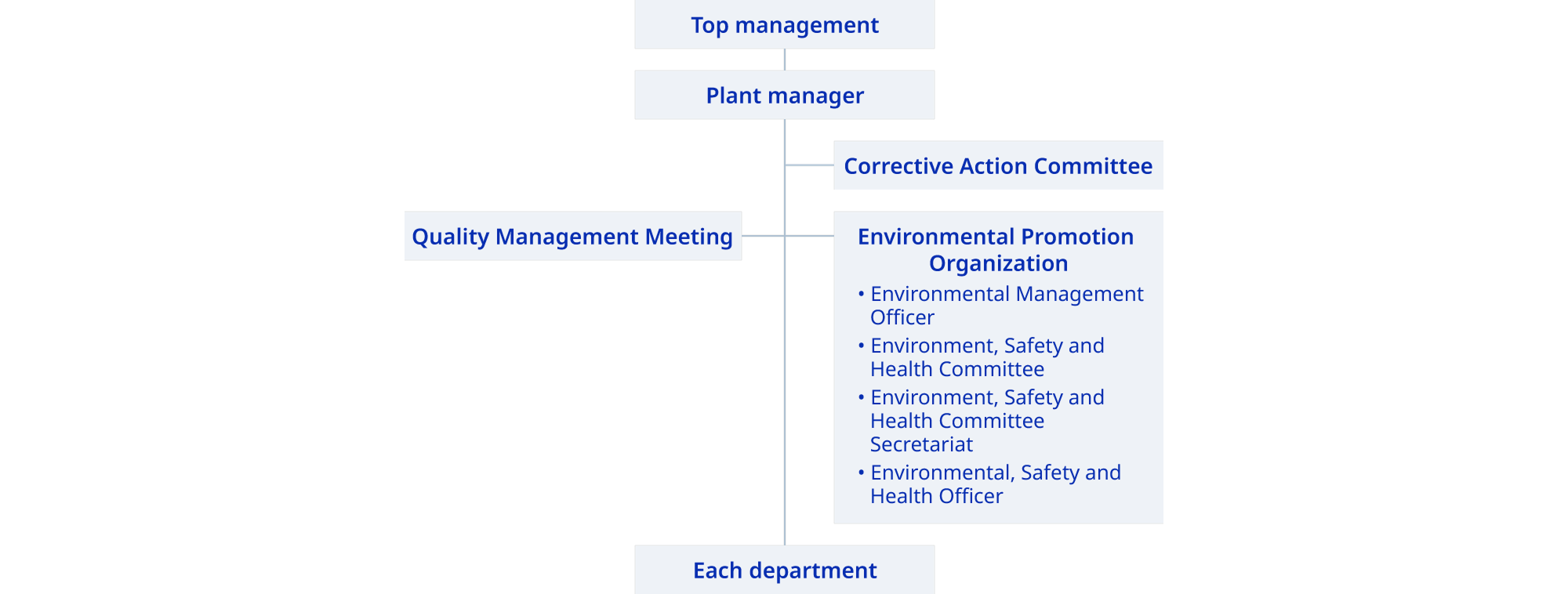

Management structure

Top management provides leadership to ensure the effective operation of the Integrated Management System across all production sites.

Top management

- Holds overall responsibility and authority for the Integrated Management System as the company’s highest-level decision-making body.

Plant manager

- Establishes fundamental principles and the Environmental Policy for environmental conservation activities.

- Reviews the Integrated Management System.

- Appoints the Environmental Management Representative and Environmental, Safety and Health Committee members.

- Exercises overall command at each plant in the event of an emergency.

- Ensures the necessary personnel, skills, technologies, and financial resources to effectively promote the Integrated Management System.

Quality Management Meeting

- Regularly reviews progress toward plant and departmental quality objectives, customer requirements, and other operational issues, reporting findings to top management.

Corrective Action Committee

- The committee convenes to address cases outlined in the Internal Quality and Environmental Audit Procedure and the Corrective and Preventive Action Management Procedure. This includes reviewing “In-Process Abnormality Reports,” “Internal Quality and Environmental Audit Nonconformity Corrective Action Reports,” and “Accident Investigation and Root Cause Analysis Reports” related to environmental, safety, and health matters.

It conducts thorough reviews to assess recurrence, effectiveness, and appropriateness of corrective actions, ensuring that each case is properly addressed and determining compliance or noncompliance.

Environmental, Safety and Health Committee

- Reviews the List of Significant Environmental Aspects, the Integrated Management Manual, and the Register of Legal and Other Requirements.

- Reviews and approves additional matters proposed by the Environmental Management Representative.

Organizational structure

Environmental initiatives

Furuya Metal implements a range of initiatives to reduce environmental impact in line with its Environmental Policy. Led by the Environmental Promotion Organization, the company sets annual objectives and promotes activities aimed at lowering environmental burden while enhancing employees’ awareness of environmental responsibility.

Visualization of environmental impact

The Environmental, Safety and Health Committee meets monthly to review and report progress toward environmental goals, fostering awareness and continuous improvement across the organization.

Key initiatives

- Improvement of energy efficiency

- Reduction of CO₂ emissions

- Reduction of water consumption and wastewater discharge

- Reduction of waste generation

Implementation of environmental patrols

The Environmental, Safety and Health Committee conducts monthly environmental patrols to verify compliance with laws and regulations, monitor energy efficiency, and check proper waste sorting at each plant. Results are reported monthly, and improvement items are addressed promptly, promoting continuous enhancement of environmental performance.

Environmental seminars

Quarterly seminars at the Tsukuba Plant provide lectures from both internal and external instructors to raise awareness and knowledge among employees. Examples include:

- August 2024: Waste management seminar

- October 2024: Oil absorbent mat handling seminar

- February 2025: High-pressure gas safety seminar

- May 2025: Protective equipment handling seminar

About ISO 14001

Furuya Metal received ISO 14001 environmental management system certification at the Tsukuba Plant in January 2006, the Tsuchiura Plant in January 2009, and the Chitose Plant in January 2011. In December 2017, the certification was updated to align with the 2015 revision of the standard.

Looking forward, Furuya Metal remains committed to global environmental preservation by driving technological innovation in areas such as clean energy, environmental purification, and industrial waste recycling. Through these efforts, the company aims to continuously minimize its environmental impact on a global scale.

History of ISO certification

| January 2009 | Tsuchiura Plant | Expansion of certification for ISO 9001 and ISO 14001 |

|---|---|---|

| March 2009 | Tsukuba Plant | Accreditation as an ISO/IEC 17025 (JCSS, International MRA) calibration service provider |

| January 2011 | Chitose Plant | Expansion of certification for ISO 9001 and ISO 14001 |

| December 2017 | Tsukuba, Tsuchiura, and Chitose Plants | Update to ISO 9001 and ISO 14001 (2015 version) |

| December 2018 | Tsukuba Plant | Update to ISO/IEC 17025 (2017 version) |

| January 2021 | Tsukuba, Tsuchiura, and Chitose Plants | Renewal of certification for ISO 9001 and ISO 14001 (2015 version) |

| December 2022 | Tsukuba Plant | Renewal of accreditation for ISO/IEC 17025 (2017 version) |

| January 2024 | Tsukuba, Tsuchiura, and Chitose Plants | Renewal of certification for ISO 9001 and ISO 14001 (2015 version) |

| February 2025 | Tsukuba Plant | Renewal of accreditation for ISO/IEC 17025 (2017 version) |