Responsible Procurement

Supply chain management

Furuya Metal (the “Company”) has established the Furuya Metal CSR Charter, a code of conduct that guides all individuals within the organization. This charter outlines the Company’s commitment to operating as a responsible corporate citizen—not only adhering to laws and regulations but also emphasizing respect for human rights, environmental protection, and fair and honest business practices, with the goal of contributing to a prosperous and sustainable society.

In line with this commitment, the Company supports the philosophy of the Responsible Business Alliance (RBA), a global coalition promoting corporate social responsibility across the electronics industry supply chain and conducts its operations in accordance with the RBA Code of Conduct.

Recognizing the importance of these standards for its suppliers and partners, Furuya Metal has adopted the RBA Code as the Furuya Metal Supplier Code of Conduct, applying it throughout its entire supply chain. Believing that mutual growth with suppliers and partners is essential, the Company strives to build and maintain strong, long-term relationships based on trust, collaboration, and a shared understanding of corporate social responsibility.

General procurement policy

- Comply with all applicable laws and social norms, both in Japan and overseas, and conduct fair procurement activities with full consideration for the environment, human rights, occupational health and safety, and corporate ethics.

- Fulfill corporate social responsibility by engaging in sound and sustainable procurement practices.

- Adhere to information security requirements and ensure that procurement activities maintain high levels of quality and safety.

Procurement procedures

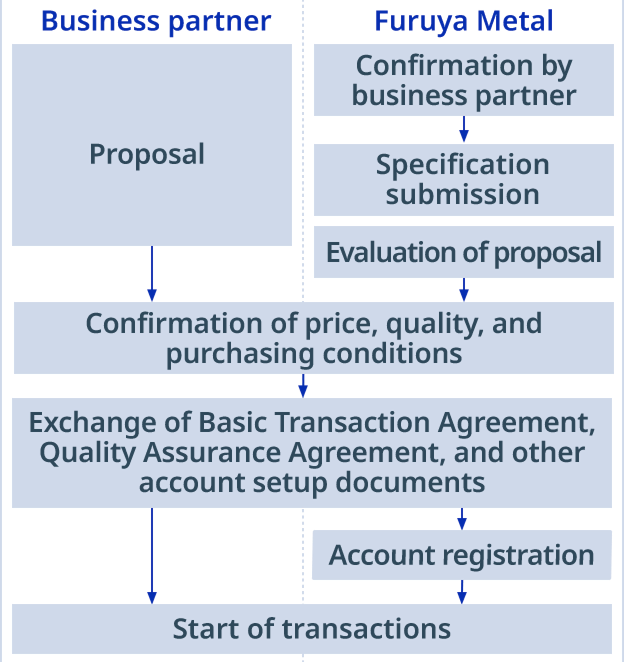

Procurement transactions at Furuya Metal are, in principle, conducted based on written contracts. For ongoing business relationships, the Company typically concludes a Basic Transaction Agreement, and, to ensure quality and safety, a Quality Assurance Agreement is also signed as standard practice.

The specific contracts, documents, and information required may vary depending on the nature of the transaction. For detailed procedures, please contact the Procurement Department.

Flow until the start of transactions

Change management

Change management is conducted in accordance with Furuya Metal’s Change Request Guidelines.

Suppliers are requested to review these guidelines carefully and, when applicable, submit a Change Request Form at least 12 months prior to the intended change.

Supplier Change Request Procedure (Japanese)(PDF:12.6KB)

For any questions or further information, please contact the Procurement Department.Responsible Minerals Procurement Policy

Furuya Metal places great importance on risk management in the procurement of raw materials, particularly those related to platinum, palladium, tantalum, tungsten, tin, and gold. The Company has established a policy to ensure that materials associated with conflict, terrorism financing, human rights violations, or money laundering are not used.

In line with this policy, Furuya Metal continuously identifies and assesses supply chain risks from procurement through to final product delivery. These risks are actively managed through the implementation of the Furuya Metal Responsible Minerals Procurement Policy, ensuring ethical and responsible procurement practices throughout the supply chain.

Furuya Metal Responsible Minerals Procurement Policy

Established: June 1, 2020

Revised: January 11, 2023 / August 6, 2024 / June 17, 2025

1. Scope

The Furuya Metal Group is committed to responsible minerals procurement across its supply chain for platinum, palladium, tantalum, tungsten, tin, gold, cobalt, and mica. The Group actively avoids procurement from conflict-affected or high-risk areas associated with human rights violations, including child labor, conflict financing, terrorism funding, and money laundering.

2. Management structure

Raw materials for Good Delivery bar production are procured by the Head Office and supplied to the Tsukuba Plant. Procurement oversight is conducted by the General Affairs and Administration Division and the Raw Material Procurement Division at the Head Office, and by the Good Delivery Bar Production Division and the Raw Material Management Division at the Tsukuba Plant.

A Responsible Minerals Procurement Manager is appointed to oversee the entire procurement management system, hold authority as defined in the manual, and ensure accountability for responsible minerals procurement. For tantalum, tungsten, tin, gold, cobalt, and mica, the Company has established a management framework aligned with the Responsible Minerals Assurance Process (RMAP) certified by the Responsible Minerals Initiative (RMI), under which the Responsible Minerals Procurement Manager promotes responsible procurement.

3. Criteria for raw material procurement from conflict-affected or high-risk areas

Suppliers suspected of involvement in conflict financing, terrorism funding, human rights violations, misrepresentation of mineral origin, or money laundering are classified as high-risk. Materials are not sourced from suppliers whose practices are considered problematic from an ESG perspective.

To identify and exclude high-risk suppliers, Furuya Metal references various information sources, including international sanctions lists, the U.S. Dodd-Frank Act Section 1502, the EU CAHRA reports, the UN Universal Human Rights Index, FATF public statements, Dow Jones Risk & Compliance Center insights, and ongoing global compliance reports.

4. Due diligence for raw materials and suppliers

Due diligence for platinum and palladium is conducted in accordance with Step 2.2 of the LPPM Good Delivery Refiners’ Guidance. The Company continuously evaluates supply chain risks, and purchases or transactions with high-risk suppliers are immediately suspended. Verification ensures sourced materials match supplier-provided information, and all due diligence and risk assessment records are properly maintained.

5. Monitoring and record keeping

Furuya Metal ensures that sourced mineral materials are consistent with supplier information. Records of due diligence activities and risk assessments are carefully maintained to support transparency and accountability.

6. Education and training

All employees involved in responsible minerals procurement receive ongoing training to strengthen compliance awareness and due diligence capabilities.

7. Third-party audits

Independent third-party audits are regularly conducted for platinum and palladium, and as necessary for tantalum, tungsten, tin, and gold, following LPPM or RMI guidance. These audits verify the effectiveness of Furuya Metal’s Responsible Minerals Procurement framework and its implementation.

8. Whistleblowing and grievance mechanism

Furuya Metal provides a reporting channel on its website that allows both internal and external stakeholders to report concerns regarding the platinum and palladium supply chain, including through anonymous submissions.

For more information about the LPPM, please refer to LPPM certification page.