Quality Assurance

Quality Policy

- We are committed to building safe, stable, and reliable production facilities.

- By thinking and acting from the customer’s perspective, we strive to deliver consistent quality and enhance customer satisfaction.

- Through continuous quality improvement, we aim to expand profitability and ensure sustainable long-term growth.

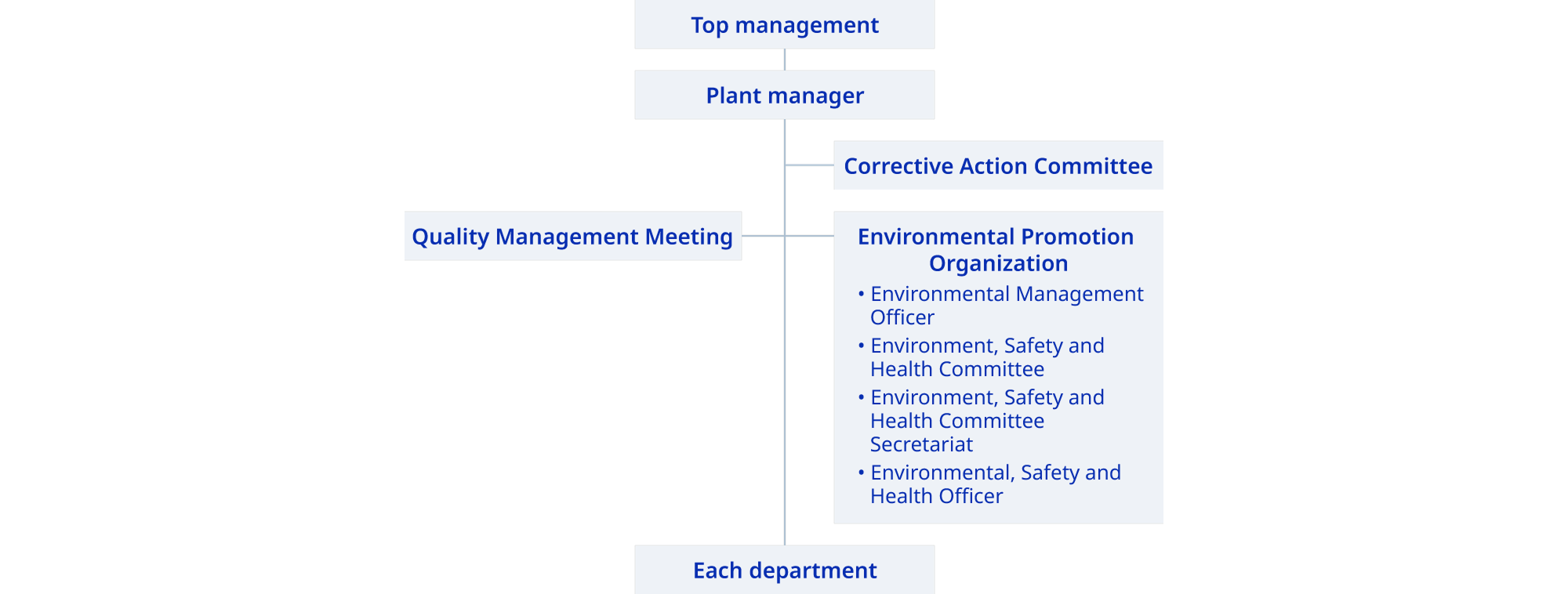

Management Structure

We designate Top Management as the company’s highest authority and strive to ensure the effective implementation of the integrated management system (ISO 14001 and ISO 9001) at each plant.

Top Management

- As the Company’s highest authority, Top Management holds overall responsibility and authority for the integrated management system.

Plant Manager

- Establishes the basic philosophy and environmental policies related to environmental conservation activities.

- Reviews the integrated management system.

- Appoints Environmental Management Officers and members of the Environmental, Safety, and Health Committee.

- Takes command of each plant in the event of an emergency.

- Provides the staff, skills, technology, and funding needed to support the integrated management system.

Quality Management Meeting

The Quality Management Meeting regularly reviews the progress of plant-level and departmental quality objectives, customer quality requirements and corresponding actions, and other issues and improvement measures. The results of these reviews are reported to Top Management.

Corrective Action Committee

The Corrective Action Committee reviews quality-related reports such as In-process Abnormality Reports and Internal Quality and Environmental Audit Nonconformity Reports, as well as environmental and safety reports including Accident Cause Analysis Sheets. In accordance with the Internal Quality and Environmental Audit Control Procedure and the Corrective and Preventive Action Control Procedure, the committee conducts closed reviews to evaluate recurrence, repetition, effectiveness, and appropriateness of corrective actions, determining conformity or nonconformity as required.

Environment, Safety, and Health Committee

This committee reviews the List of Significant Environmental Aspects, the Integrated Management Manual, and the Register of Legal and Other Requirements. It also reviews and establishes other matters proposed by the Environmental Management Officer.

Management structure

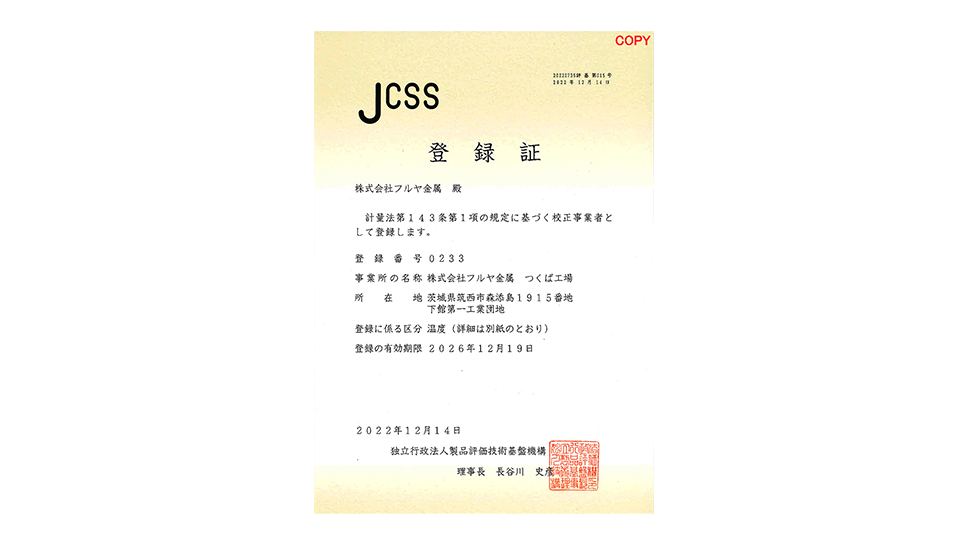

ISO9001/JCSS

Furuya Metal obtained ISO 9001:1994 certification in February 2000. This certification was subsequently updated to ISO 9001:2008 in December 2009 and to ISO 9001:2015 in December 2017.

All products manufactured by the Company are managed under its Quality Management System. We strive to maintain and expand these certifications to meet customer needs and expectations.

In March 2009, the Company was accredited as a JCSS calibration operator (compliant with ISO/IEC 17025) for the calibration of R-type thermocouples under the international MRA framework. This accreditation was renewed under the 2017 version in December 2018 and again in December 2022, valid through February 2025.

Furuya Metal remains committed to delivering even higher quality in accordance with international standards.

ISO certification milestones

| January 2009 | Tsuchiura Plant | Certification scope expanded to include ISO 9001 and ISO 14001. |

|---|---|---|

| March 2009 | Tsukuba Plant | Accredited as a JCSS calibration operator (ISO/IEC 17025) under the international MRA framework. |

| January 2011 | Chitose Plant | Certification scope expanded to include ISO 9001 and ISO 14001. |

| December 2017 | Tsukuba, Tsuchiura, and Chitose Plants | ISO 9001 and ISO 14001 updated to the 2015 version. |

| December 2018 | Tsukuba Plant | ISO/IEC 17025 accreditation updated to the 2017 version. |

| January 2021 | Tsukuba, Tsuchiura, and Chitose Plants | ISO 9001 and ISO 14001 (2015 version) certification renewed. |

| December 2022 | Tsukuba Plant | ISO/IEC 17025 (2017 version) accreditation renewed. |

| January 2024 | Tsukuba, Tsuchiura, and Chitose Plants | ISO 9001 and ISO 14001 (2015 version) certification renewed. |

| February 2025 | Tsukuba Plant | ISO/IEC 17025 (2017 version) accreditation renewed. |

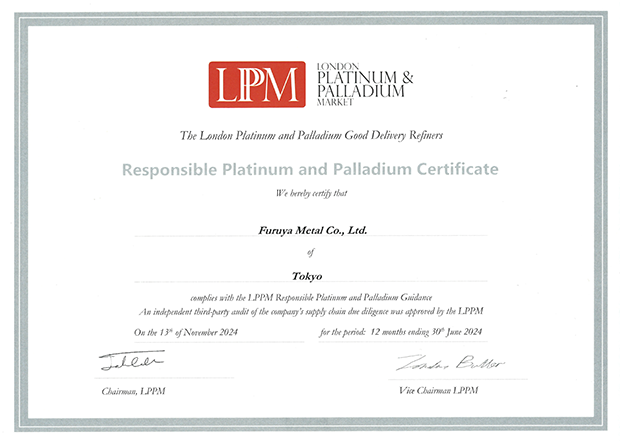

LPPM Certification

The London Platinum and Palladium Market (LPPM) is the world’s only authoritative organization that certifies and registers Good Delivery refiners, ensuring the fair and proper trading of platinum and palladium internationally. Established in London in 1989, the LPPM operates a globally trusted accreditation system recognized throughout the precious metals industry.

Furuya Metal obtained LPPM Good Delivery certification in 2005. To be accredited under the LPPM Good Delivery program, refiners must meet the following criteria:

- Ability to produce high-purity platinum and palladium ingots or plates

- Compliance of ingots and plates with LPPM standards for appearance, weight, dimensions, and stamping

- Sound financial standing and a proven track record of business operations

- Establishment of a responsible sourcing system with consideration for environmental and ethical practices

Meeting these stringent standards means that companies holding LPPM Good Delivery certification are recognized as reliable and trusted members of the global precious metals industry.

Please refer to the Commitment to Analytical Technology page for details about our analytical capabilities. For more information on responsible sourcing, see the Responsible Minerals Procurement Policy page.